You may have tried to mobilize Operation: Organize the Warehouse, or it may be on the “TO DO” list. Because there is never enough time, or space, in our restoration businesses, we need to plan, schedule, and make it happen. Described in the article, “Roll it Uphill – A Lesson in Leadership”, is the mindset of taking action and leading the way instead of placing blame on your team for the things that don’t get accomplished. Take the example of a new piece of expensive equipment that gets lost and forgotten in a messy collection of equipment, cords, and supplies. It happens all the time, right? What would be the result if the thought process was more of the following…

- Does the new piece of equipment have a designated, labelled place where it belongs?

- Did this designated place get communicated to the team?

- Does the rest of your equipment and supplies have assigned shelf or floor space?

- Do you currently have space capacity for additional equipment? Might it have been better to rent it?

In the article, Improving Effectiveness, Efficiency, Profitability by Looking outside the Industry, you will find inspiration in other industries that could best help us design and maintain the warehouse. In disciplines described, you will find simple approaches and guidance that will help you lay-out and organize your production and storage areas in a way that will maximize your efficiency and reduce your headaches.

To move it off the list of dreams and goals and make it a reality, let us focus on what is to be gained:

- Efficiency: Operation efficiency is tied to reducing the number of resources needed to deliver a high-quality product or service. In this case, decreasing the amount of time required to locate, mobilize, clean, maintain and repair your equipment and supplies will increase:

- Profitability

- Productivity (which also results happier work force)

- Customer Service

- Asset Management: Our equipment, supplies, and if you do contents, the responsible custody of customer property, is an important part of our operation. The better we can track, maintain, and care for our assets, the better our operational results.

- Credibility and Pride: In our eLearning lesson on the custodial closet, instructor Mark Warner describes this area as the “back of the house” and explains that during an audit, the first place he inspects is the “back of the house.” The general organization, housekeeping and cleanliness of this space is the evaluated. In our industry, the warehouse, is the “back of the house” and is a reflection on the company.

- Mindset and Culture: As we produce clean and healthy environments for our customers, it is vitally important for us to provide a facility that exemplifies quality, efficiency, and pride. This creates a culture and mindset that is reflected in the personal appearance of our staff, their vehicles, and the condition of the jobsite. If we expect clean, organized, and safe job sites, it starts with how well we manage and control our shop or warehouse.

The following is a practical list of steps offered not as an expert in the field but as an accountant-turned-restorer with a passion for our operations, workflows, and cultures. Depending on your status, you may adjust the list to meet the needs of your organization.

Before executing your project, I offer the following tips, and my joke for managing anything is, “It is just like running a restoration job!”

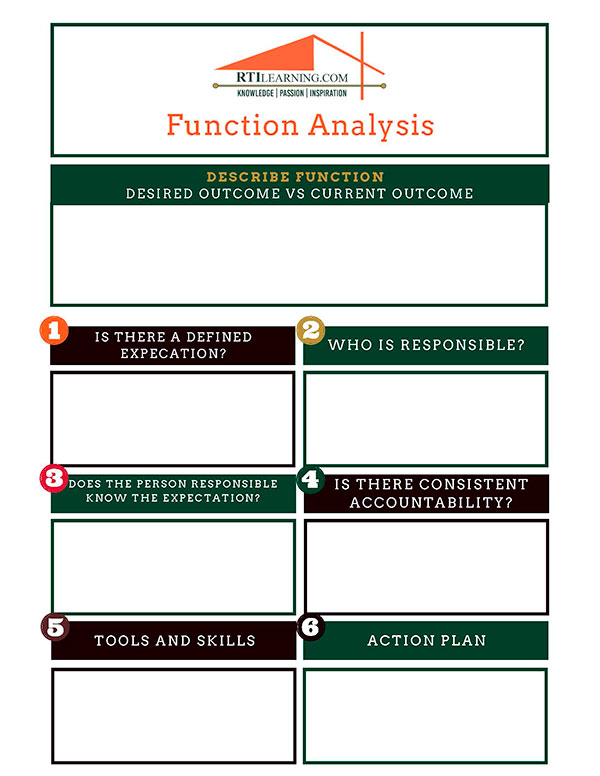

- Assign and grant the authority to a project manager who is ultimately responsible for goals, objectives, and managing the resources.

- Each task should have a clearly defined expectation, a person assigned to the successful execution, and start dates and completion dates.

- As a project, formalize periodic updates and adjust the plan as needed.

Simple Steps:

- Assign a project manager and consider a project team.

- Evaluate your space.

- Look at it with fresh eyes.

- What is working, what is not working?

- Evaluate your Inventory.

- Supplies, Equipment, Tools, Contents, Other.

- Get rid of what you do not need or use.

- Consider how your inventory is used in your workflows.

- Design the space in support of inventory, workflows, services, and needs. Sketch out several layouts using the following tips:

- Maximize space and fully utilize the volume of your space.

- Allow for safe and clear walkways.

- Consider the organization systems that you may need like, shelving, hooks, etc.

- Other considerations such as Safety and Cross-contamination

- Designate locations for the inventory and use the following tips in making these assignments:

- Efficient workflows that consider our movements, frequency of use, proximity to loading, weight of the equipment and supplies, and service commonality. An example is we do not want to put a piece of equipment on a shelf that is 12 feet overhead that is used daily. We want to minimize the movement and time it takes to gather necessary supplies and equipment to clean a carpet.

- Utilize best practices and traditional vocabulary in warehousing and make it part of your culture.

- Example: Zone | Aisle | Rack | Shelf | Bin.

- The Vacuum is stored in Zone A, Aisle 2, Shelf 1, Bin b = A.2.1.b

- Workspaces may include the need to accommodate:

- Contents

- Equipment cleaning, maintenance, repair

- The movement of forklifts or pallet jacks

- Choose an Inventory Management System / software solution and maintain it.

- The system should support designated storage location and movements. You can read more here: Restoring Success, Inventory Management

- Plan for the pieces will present you with a graphic on the movement that must be accounted for and other considerations in maintaining your warehouse system.

- Acquire all tools and supplies needed to support the plan:

- Shelves, dividers, hooks

- Tape: Use the proper tape on the floor to create zones, aisles, walkways, and other designations in support of your design.

- Ladders, forklifts, other tools, and systems that supports the safe accessibility of the inventories.

- Signs, labels, and color coding are some simple solutions that will help the team utilize and maintenance of the system. Consider a grocery store, with signs telling us where to find condiments. You would not put an air mover in a spot for the condiments! (Bad restoration joke?)

- Supplies Management:

- Establish documented minimum and maximum supply inventory levels that is appropriate for the space designed. Having a two-year supply of X is not practical for maximizing our warehouse space.

- Establish a restocking protocol that rotates the supplies in accordance with a First In – First Out approach. This will ensure a rotation and avoid potential spoilage of your supplies.

- Job costing can be supported if it is part of your supply management systems.

- Maintaining the Warehouse: As part of the operations, protocols, the systems, and warehouse need to be maintained so that the company and team can continue to enjoy the benefits of the project.

- Establishment of Receiving Protocols. A few examples to consider:

- Reviewing shipping documents, reconciling them with the shipment and forwarding the slips to accounting

- Cleanliness: New supplies are sometimes received and covered in dirt and grime. We do not want dirty supplies on our shelves and worst, yet we do not want them landing on a job site.

- Have clearly defined expectations and assignment of responsibilities in all cleaning and maintenance related efforts.

- Person assigned (rotation)

- Frequency Schedule

- Use of a checklist.

- Visual Inspections and Supply Checks:

- Assigned and periodic inspections

- Supplies, even with a digital management solution, should have assigned and periodic inventory checks.

- Establishment of Receiving Protocols. A few examples to consider:

Warehouse management is an ongoing practice that helps our operation, efficiency and can inspire the team. As with much in our industry, changes, technology, and evolution, will often require on-going redesigns of the space and systems. I have seen many beautifully organized and clean warehouses in my travels. Those of you who have mastered the feat of keeping order in the chaos, please share your tips in the comments below. May your well-planned, systems- driven, and organized warehouse bring you much Restoring Success.

By

By  By

By

Restoring Success

Restoring Success